Indoor Cultivation

Introducing CO2 into the air during the various stages of plant growth is like providing steroids to the plant. You will get:

- Increase yield by up to 50%

- Get full harvest in 7-8 weeks.

- Plants and leaves will become more compact and denser

Successful CO2 management can boost yield and prevent pest and environmental issues in the grow space. The photosynthesis process requires a careful balance of CO2 with light, temperature and humidity. Lower carbon dioxide concentrations can seriously impede plant growth and general health. In fact, a drop of 25% in natural CO2 concentrations can easily inhibit growth by over 50%. Consequently, the grow room should be set up to replenish CO2 levels throughout the daytime using ventilation systems to ensure the CO2 levels are adequate.

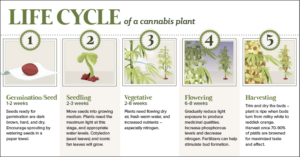

Optimal CO2 levels vary across different plant growth stages: 600-1200 PPM for seedlings and 800-1500 PPM for vegetative and flowering/blooming stages. CO2 supplementation is unnecessary during night hours as photosynthesis ceases and plant metabolism is dominated by respiration.

Another use of carbon dioxide (CO2) is in the extraction industry. Supercritical extraction is the process of separating one component from another using a supercritical fluid as the solvent. CO2 is known as a “tunable solvent” making it extremely versatile for creating a multitude of end products by controlling temperature and pressure. CO2 extraction allows you to create a pure, clean, quality oil that is safe to produce with little-to-no post-processing. Processes that use toxic solvents may require many hours to purge the solvent trapped in the oil. Multiple industries have proven that the highest efficiencies in commercial processing utilize CO2. With CO2 you can target specific compounds, like terpenes (terpenoids) and THC/CBD (cannabinoids) through different operational parameters. CO2 is also a sanitizing agent, prolonging shelf life, and, with the proper system and environment, yields food and medical grade oils. CO2 extraction is a safe, clean, and highly-versatile method of extracting plant botanicals, essential oils and more.

Safety measures including CO2 alarms must be in place when dealing with CO2, especially in larger grow rooms, as excessive levels can be harmful.

Broward Nelson provides the the indoor cultivation industry with “one stop shopping” for their CO2 tanks, CO2 controllers, CO2 alarms & CO2 regulators. Broward Nelson provides CO2 via both high pressure cylinder manifolds and bulk CO2 systems to run growhouses and extraction operations. Our service is second-to-none and our drivers are friendly and knowledgeable.

Frequently Asked Questions

Like other green plants, cannabis transforms light energy into chemical energy via photosynthesis. During this process, the plant uses sunlight to convert water and CO2 into carbohydrates (sugars) that plants use to grow.

Increasing the amount of CO2 in the air for your grow space can promote faster growth and productivity. Photosynthesis is directly linked to the amount of CO2 available to the plant. If you are looking to accelerate the growth cycle of your crops it is important to consider adding additional carbon dioxide into your space.

For those that are looking to add carbon dioxide to their grow room, the flowering stage is the most important. It is critical that when you supplement CO2 to your crops you do so within the first 2-5 weeks of flowering. Assuming your light, heat, water and nutrients are fine-tuned, this can boost overall crop size by 20-25%.

Please visit the following link to calculate your CO2 needs based on the volume of your space.