CO2 Life Safety

CO2 Monitoring

Our CO2 monitoring system is designed to protect customers and workers near stored carbon dioxide.

Our CO2 monitoring system is designed to protect customers and workers near stored carbon dioxide.

A CO2 alarm from Broward Nelson will provide audible (loud beeping) and visible (strobe light) notifications when CO2 levels are considered unhealthy / dangerous in accordance with existing safety codes in the area being monitored.

The CO2 alarm is easy to install and use. As your CO2 storage needs increase, additional sensors and alarms can be added to the system.

Locations may include:

- Breweries

- Soda fountain syrup racks

- Walk in coolers

- Draft beer boxes

- Storage closets

- Pool equipment rooms

Broward Nelson’s CO2 alarm meets all OSHA, NFPA 55, IFC and State Code requirements for CO2 alarms in restaurants, bars and more.

Compliant with US Regulatory & Safety Codes

• National Board Inspection Code Part 1 Supplement 3.

• National Fire Protection Association 55 Compressed Gases and Cryogenic Fluids Code.

• Compressed Gas Association G-6.5.

• International Fire Code.

• OSHA Compliant.

Call 800.262.8265 to speak directly with one of our CO2 alarm specialists or Click Here to e-mail us and let us show you how Broward Nelson Fountain Service’s products, quality, service and delivery can help add dollars to your bottom line!

Frequently Asked Questions

CO2 is a colorless odorless gas that is defined as a simple asphyxiant and is classified as a hazardous material. Co2 can be maintained in bulk tanks at pressures between 150 psig & 300 psig. Co2 in cylinders run a higher pressure, between 700 psi & 1000 psi. Additional precautions must be considered when handling CO2 and vessels under pressure

CO2 can be dangerous in enclosed spaces. With CO2 cylinders NEVER: connect a gas cylinder directly to a keg, throw or drop a gas cylinder or connect the cylinder to anything without a pressure relief mechanism on it. Remember to always ventilate the area where you are working with CO2 and always secure the cylinder during and after use.

CO2 monitors are used in restaurants, indoor greenhouses and breweries that use tanks or cylinders of compressed CO2 to warn workers of a CO2 leak.

Ask your local fire inspector to provide details about the specific code you are being asked to meet. Typically, it will be a local code, the International Fire Code, the National Fire Protection Association Code or the National Board Inspection Code.

Outside storage of tanks is allowed without a CO2 monitor but the gas being used inside requires a monitor. The points of use are typically BIB racks, beer coolers or any manifolds where beverage gas lines converge.

If you suspect a CO2 leak, leave the area immediately and alert others to do the same. Call emergency services to report the leak. Do not try to stop the leak or investigate the source of the leak yourself.

Modern CO2 sensors use non-dispersive infrared (NDIR) technology. The sensors detect the absorption of infrared light at a wavelength equal to the size of a CO2 molecule in a sample of air. The amount of infrared light measured is proportional to the number of CO2 molecules in the air. The monitor then displays the CO2 levels in parts per million (ppm) on a screen, in an application or sends it to another device that controls an alarm system.

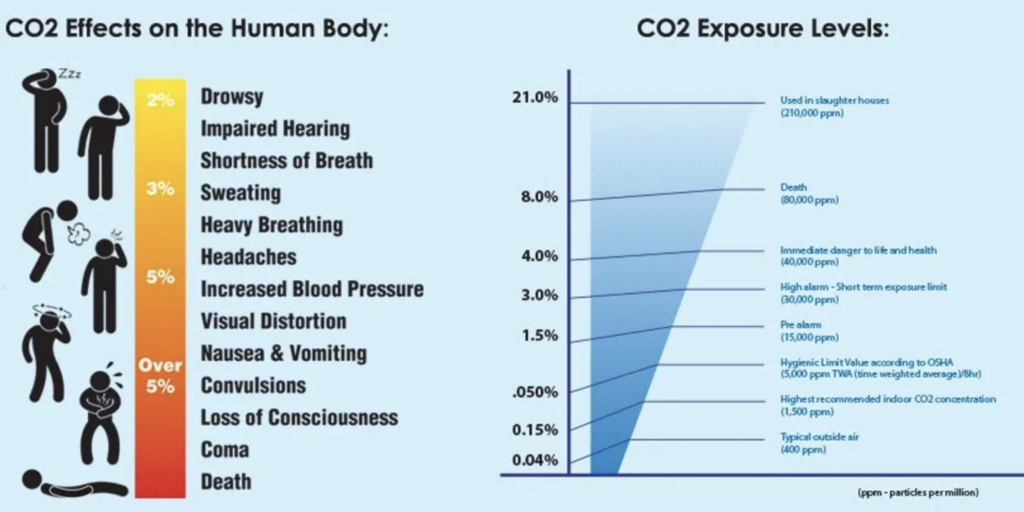

High levels of carbon dioxide can lead to symptoms such as headaches, fatigue, dizziness and nausea. Prolonged exposure to high levels of carbon dioxide can also lead to more serious health issues, such as respiratory problems and asphyxiation.